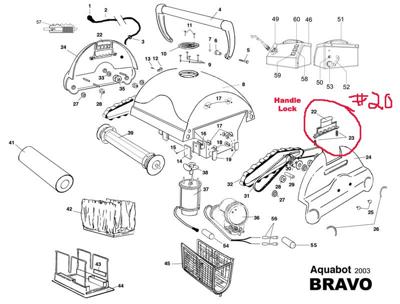

Use a cotton swab to dry all sides of the Fuse and Fuse Holder (inside and out). Cable Assemblies – With the Power Supply unplugged, check the Power Cable (Ref.# 4.6) and the Floating Cable for cuts or damage. If you detect damage to either Cable, please contact our Customer Service Department at 1-800-845-4856. View the PDF for more information. Aquabot Repairs - Authorize Aquabot Dealer - Pool Cleaners, Service & Parts - 1.973.415-7195. Aquabot Bravo Repair Manual El Aprendiz De Brujo 2 Libro Pdf Antes 10/9/2019 Dr Feodor Jagor And Jose Rizal. Read Now He first arrived at MARSEILLES. During his summer vacation Rizalwent to Paris and stayed there fromJune 17 to august 20, 1883 toobserved how medicine was beingpractice there and returned toMadrid. After his studies in Madrid.

My turn to rebuild the pump

Aquabot Elite Manual

Aquabot Bravo Manual

I bought the very 1st run of Aquabot Turbo T-4 robots in 2005-2006. Paid $1500 which is costly. So when I had even the slightest problem, I called Aquabot tech support. It wasn't long before Aquabot's technician knew me by name. And this afforded me much seat time for learning everything there is to know about Aquabot pool robots. So worth it.After 7 years the pump failed. I took it apart. The oil was like water. Probably because water leaked in from the pool. Some older pump motors had no silicon/resin for waterproofing. But still, I got 7 years of heavy use. Pretty good mileage. Internally, I found excessive corrosion, damaged/leaking caps, tarnished copper pump windings, etc. I had no patience to figure out how I could salvage this.

So the search was on for the best deal on a new pump. 1st order of business was to call the Aquabot technician to verify the part #. Seems there were a couple pumps offered. Well, the Aquabot technician revealed some very valuable info:

Many Aquabot's have the 'POWER WASHING' feature. The pump motor used for these Aquabots has a POWER WASHING ADAPTER KIT mounted underneath the impeller. This pump motor assembly is often priced in the $300 range.

Now that was 5 years ago. That pump just failed 2 days ago. I now have the same issue but after opening THIS pump, it is very clean inside. I saved the oil. I carefully removed the resin and identified the caps, their respective specifications, & their orientation. I am DEFINITELY going to replace the caps this time. 1 collapsed & leaked. I am fairly certain that's what failed

You can read the rest of this post for the specific details regarding the materials I am using for this repair or even better, I made a list on Amazon that can be viewed publicly & it shows the exact items i purchased. Check it out @ the following address

https://www.amazon.com/gp/registry/wishlist/2V9ARV7DSAD7H/ref=cm_wl_huc_view

Or, continue reading to see the list of materials with details. I will be repairing the pump motor on July 6th, 2017 & will post my experience

Here is the list of items I actually bought & the price paid.

1) 5pk of NICHICON UPW1J681MHD1TN ALUMINUM ELECTROLYTIC CAPACITORS:

-680UF 63V 1000hrs@85C

-Low impedance w/high reliability

-Good for startup/run capacitor applications

-Price Paid - $10.80

2) 25pk Wiwaplex Heat Shrink Butt Connectors Crimp Electrical Terminals

-waterproof wire connector

-Red 18-22 A.W.G

-Price Paid - $6.99

3) 85pk 3:1 Dual Wall Adhesive Heat Shrink Tubing kit

-6 Sizes(DIA): 1/2' 3/8' 1/4' 3/16' 1/8' 3/32'

-Best Cable Sleeve Tube Assortment

-Storage Case for DYI by MILAPEAK (Black)

-Price Paid - $9.89

4) 1 lb. Pug Gardner Bender DS-110N Duct Seal

-add on item ($25 minimum purchase)

-Price Paid - $2.98

5)Sikasil N-Plus White Silicone Sealant/Caulk 10.1 fl. oz. Cartridge

-100% RTV neutral cure silicone sealant

-Price Paid - $8.50

In total, I spent about $40. I only have 5 new capacitors, 4 of which will be used but other than having to buy another set of caps, I have several more butt connectors, plus enough shrink tubing & sealant for 10 or more pump motor repairs. If I use 5 years as a reference for repeating this repair, I can just buy a set of 4 caps for less than $10 if & when the need arises, and I can just store the remaining materials for future use. So, if I DO need to do this again, It should only require a set of caps.

I've been taking photos of the progress thus far but it's not really hard to see what's going on here. 4 total capacitors wired in parallel. I had 63v caps rated @ 470uf but I opted for replacements that were 63v 680uf only

because I was able to get them shipped to my door in 2 days. All 5 items I ordered will be here the same day which was a stroke of good luck. If anyone blows the fuse in the main power supply to the aquabot, mine uses a glass tube buss 2.5a x 250v. Just wanted to include as much info about the entire Aquabot System for anyone who might be seeking details and specs

And for those who have the pump motor with the 'PRESSURE WASHING ADAPTER KIT' & you buy the cheaper pump motor withput the kit, just follow the instructions for transferring the PRESSURE WASHING ADAPTER KIT from your old pump to the new. Here is a link to the pump without the kit

http://www.robotshop.com/en/aquaproducts-jet-series-pump-motor.html#description

Super great deal @ $179 w/free shipping, no tax